High efficiency PVC sheets granulator

- Model

- SPG700

Review

Description

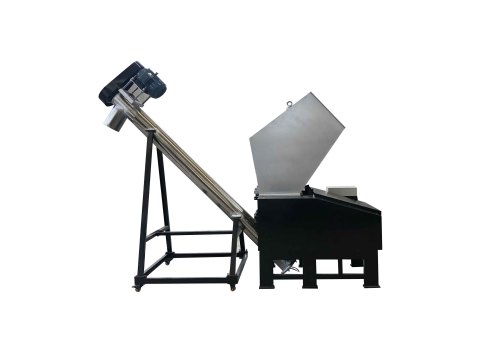

High-efficiency Plastic granulators

Use for shredding plastic into small pieces, is probably one of the most popular

types of plastic recycling machinery

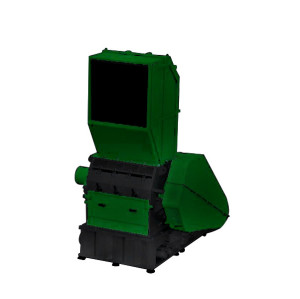

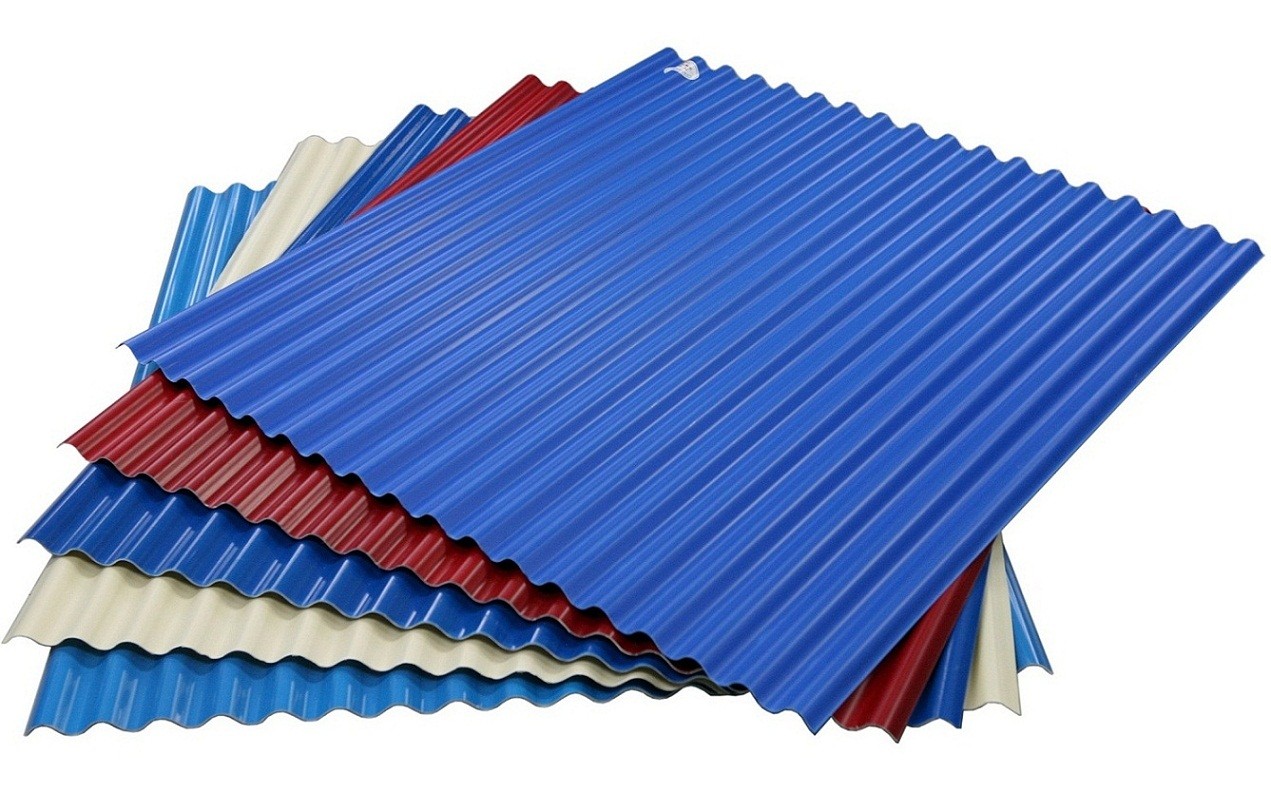

A plastic granulator is a machine used for size reduction, an essential step in plastic recycling. Plastic granulators have the ability to quickly break down plastic products such as plastic films, sheets, pallets and pipes into small, uniform pieces called “regrinds” or “flakes”. In some cases, this maybe the only step required before it can be reused in manufacturing new plastic products. For the most part, however, recycling of plastic scrap requires much more resources in sorting and separation, size reduction, washing, and pelletizing.

In a plastic granulator, cutting knives are mounted on an open rotor spun to high speeds by an electric motor. This rotor is encased in a cutting chamber where stationary knives are mounted. As the plastic scrap enters this cutting chamber, the rotating knives come into contact with the stationary knives cutting the plastic into little pieces. A large screen with many holes is placed at the bottom. The plastic will continue to mix and be cut by the knives until it is small enough to fall through this screen. Hence, by adjusting the size of the holes, one can control the size of the cut shreds.

|

Model

|

SPG700

|

|

Shredding materials

|

PVC shheet with 5mm thickness

|

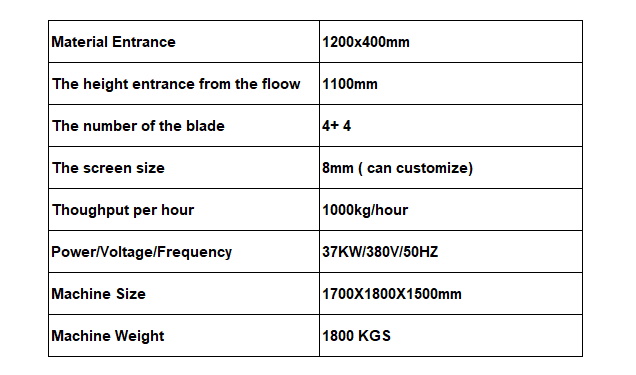

Material Entrance | 700(L)* 400(W)mm |

Working Capacity | 400-600 kgs/hour |

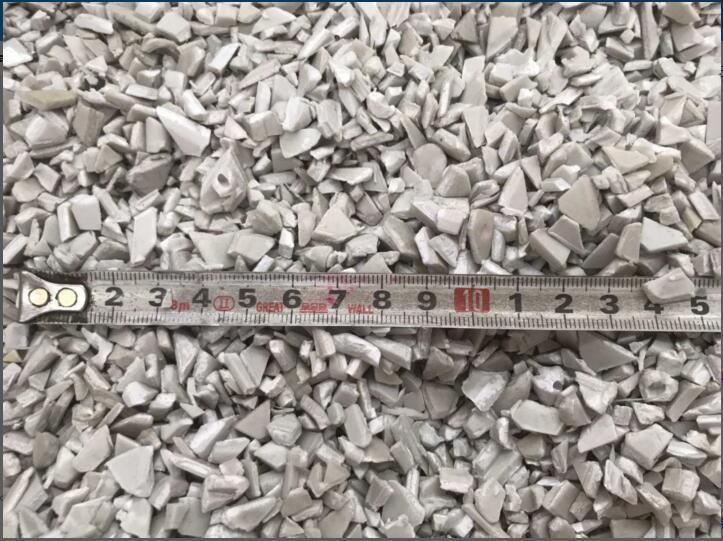

Shredding particle size | 5mm - 12mm |

Motor power | 32.2 KW |

|

Machine size

|

1600 (L)* 1300(W)* 2050 (H)mm

|

|

Machine weight

|

1450 KG

|

*High-efficiency motor

*Hardened cutting blades and

teeth cutters

*Safety interlocks

*Obstruction alarm

*Reduce logistic cost

*Shredding plastic into small pieces