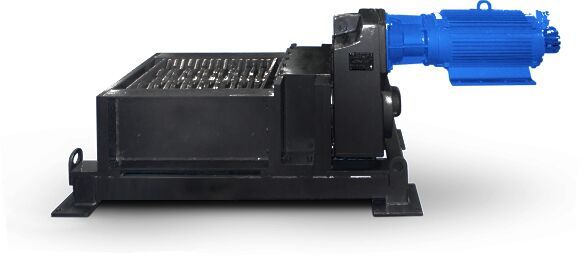

twin shaft plastic shredder for plastic recycling

- Model

- SPT600

Review

Description

Waste plastic bottle and tyres recycling double shaft shredding machine

The shreds are directly discharged after cutting without passing through a screen, so the size of shreds is quite random, custom blade widths can match your required sizing. Programmed Reveres rotation of the rotor shaft can prevent damages when overload.

Both electrical and hydraulic drive systems available.

Application:

Specially design for shredding plastic meterials, such as waste tyres,waste plastic bottle,plastic durms and waste rubber materials

- Advantages:

*Dual-shaft/dual-rotor design with differential shaft speeds

- *Heavy duty internal gearbox

- *Custom blade widths to match your required sizing

- *High Alloy blades materials with optional hard-facing to increase cutting effectiveness

- *Recirculation systems for multi-pass processing if needed to meet required size reduction

- *Choice of drive system (hydraulic or electric)

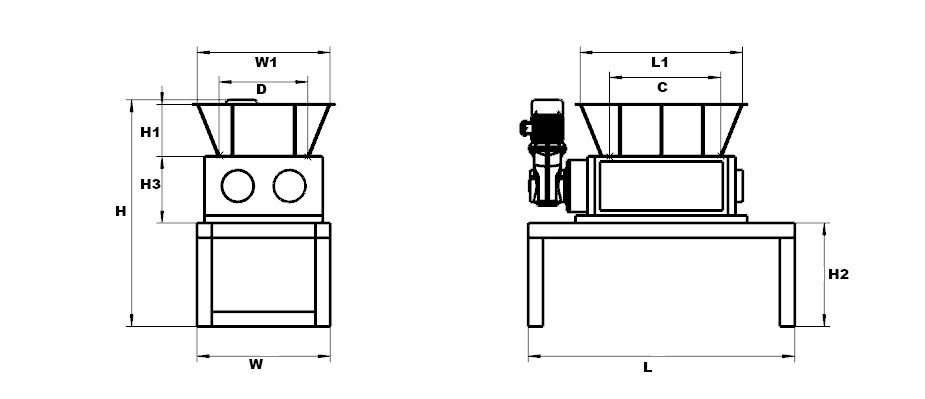

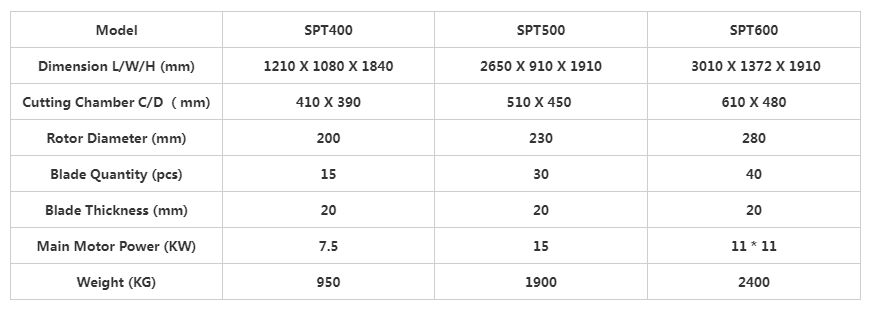

Technical Date:

|

Model

|

SPT400

|

SPT500 | SPT600 |

|

Dimension L/W/H (mm)

|

1210 X 1080 X 1840

|

2650 X 910 X 1910 | 3010 X 1372 X 1910 |

|

Cutting Chamber C/D (mm)

|

410 X 390

|

510 X 450 | 610 X 480 |

Rotor Diameter (mm) | 200 | 230 | 280 |

Blade Quantity (pcs) | 15 | 30 | 40 |

Blade Thickness (mm) | 20 | 20 | 20 |

Main Motor Power (KW) | 7.5 | 15 | 11 * 11 |

Weight (KG) | 950 | 1900 | 2400 |

The size of shreds is quite random, custom blade widths can match your required sizing