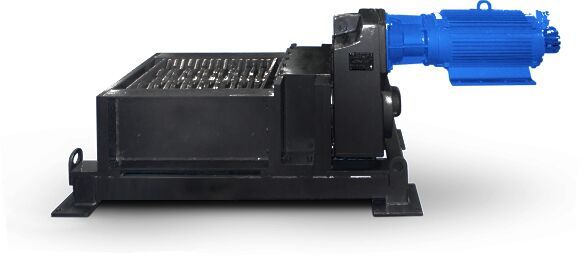

Industrial waste cardboard box and paper core shredder

- Model

- SPT150

Review

Description

High efficiency cardboard box and paper core shredder

The volume of paper or cardboard that larger box plants use is immense. Every day tons of heavy paper reels are processed. With each processed reel remains a core that has to be recycled. This can present board plans with a real headache and added expense.

Such cores are a special challenge for the downstream recycling process. Without any particular pre-treatment, they can damage traditional conveyor belts and balers. This damage can mean a plant’s own waste treatment plant is down for days, resulting in heavy repair and lost time costs. Because of this risk to machinery, cores are often separated out and often disposed of at a fee.

Such cores are a special challenge for the downstream recycling process. Without any particular pre-treatment, they can damage traditional conveyor belts and balers. This damage can mean a plant’s own waste treatment plant is down for days, resulting in heavy repair and lost time costs. Because of this risk to machinery, cores are often separated out and often disposed of at a fee.

Gator offers a new and improved solution. Instead of risking machinery and efficient, or paying additional fees foroutsourced recycling options.

Application:

Specially used for shredding waste cardboard, paper, box and paper core etc

Technical Date:

|

Model

|

SPTS150 |

||

|

Maximum Cardboard Feeding Width

|

1500mm |

||

|

Maximum Paper Core Diameter

|

120mm |

||

Maximum Paper Core Thickness | 30mm | ||

Maximum Cardboard Thickness | 80mm | ||

Blade Shaft Rolling Speed | 480 r /min | ||

Main Motor Power (KW) | 18.5 KW | ||

Shredding Capacity | 1000-2000 KG/hr | ||

Machine Weight (KG) | 2800 KG | ||

Machine Size | 2130 (L)* 1630 (W) * 1849 (H) mm |

The size of shreds is quite random, custom blade widths can match your required sizing