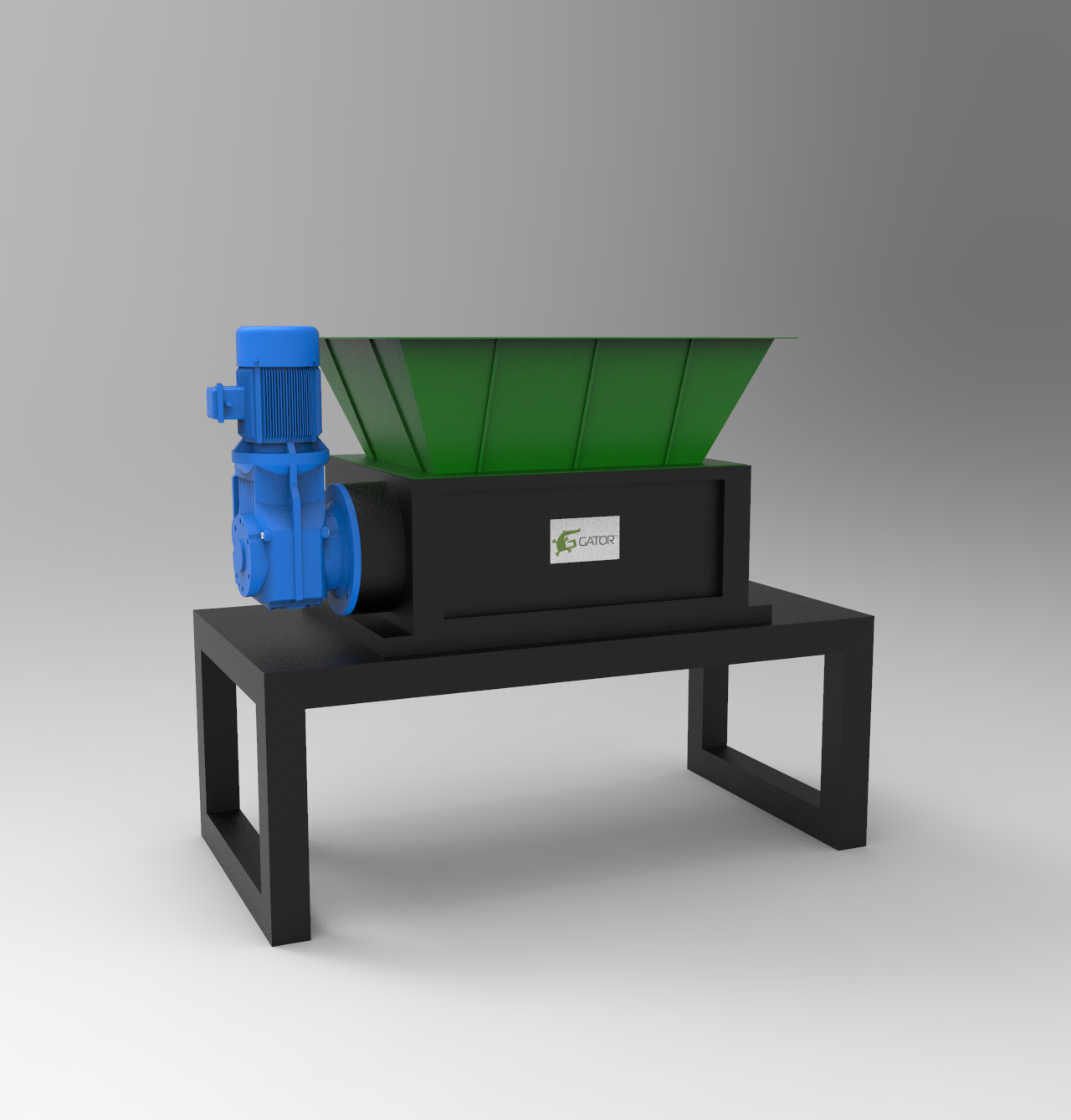

two shaft shredder Small-size For shredding solid waste, E-waste, plastic, metal and wood waste

- Model

- SPT400

Review

Description

Two Shaft Shredders: High Torque Shredding Technology.

Two Shaft Shredders is featured sophisticated design, robust structure, and high efficient shredding result, two shaft shredders are normally used first stage shredder for materials like truck tires, steel drums, organic waste, and MSW, With a two shaft shredder, once the materials is fed into the cutting chamber, the cutting blades with hooks will grab material and then shear it down to strips.

The shreds are directly discharged after cutting without passing through a screen, so the size of shreds is quite random, custom blade widths can match your required sizing. Programmed Reveres rotation of the rotor shaft can prevent damages when overload. Both electrical and hydraulic drive systems available.

Application:

*Paper - Documents, waste paper;

*Plastic- Reclaimed plastic, waste plastic;

*All types of tires— Car tires, van tires, truck tires, mining tires etc;

*Packing materials: Cardboard and woven sacks;

*Metal— scrap car, waste metal sheet, baled aluminum, metal drum etc.

*E-waste— WEEE waste, printers, refrigerator, cooper wire cable, printed circuit boards etc.

*Wood— Wood pallets, wood block, waste wood.

*Solid waste- MSW waste etc.

- Advantages:

*Dual-shaft/dual-rotor design with differential shaft speeds

- *Heavy duty internal gearbox

- *Custom blade widths to match your required sizing

- *High Alloy blades materials with optional hard-facing to increase cutting effectiveness

- *Recirculation systems for multi-pass processing if needed to meet required size reduction

- *Choice of drive system (hydraulic or electric)

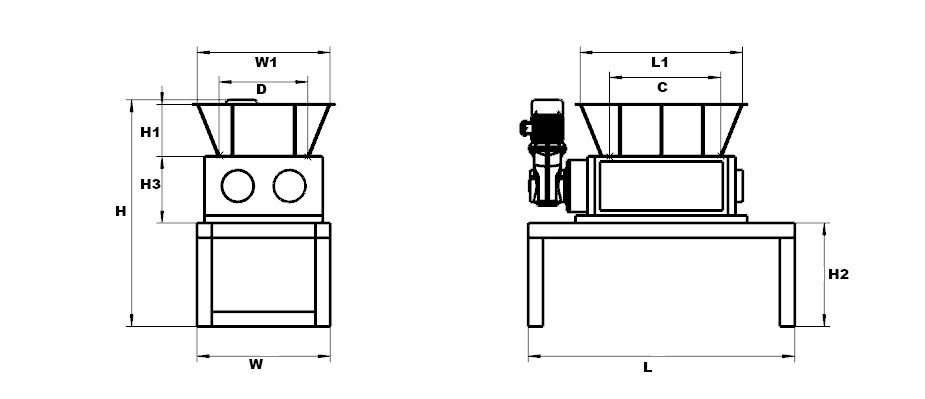

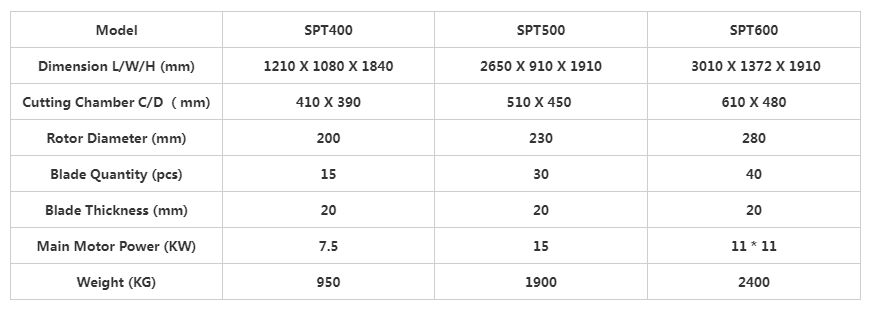

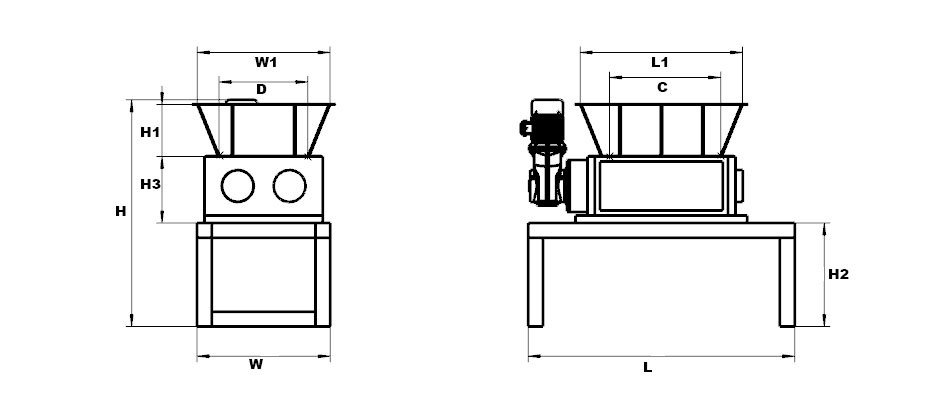

Technical Date:

|

Model

|

SPT400

|

SPT500 | SPT600 |

|

Dimension L/W/H (mm)

|

1210 X 1080 X 1840

|

2650 X 910 X 1910 | 3010 X 1372 X 1910 |

|

Cutting Chamber C/D (mm)

|

410 X 390

|

510 X 450 | 610 X 480 |

Rotor Diameter (mm) | 200 | 230 | 280 |

Blade Quantity (pcs) | 15 | 30 | 40 |

Blade Thickness (mm) | 20 | 20 | 20 |

Main Motor Power (KW) | 7.5 | 15 | 11 * 11 |

Weight (KG) | 950 | 1900 | 2400 |

The size of shreds is quite random, custom blade widths can match your required sizing