Automatic baler hydraulic Heavy duty baler for paper, cardboard and film waste.

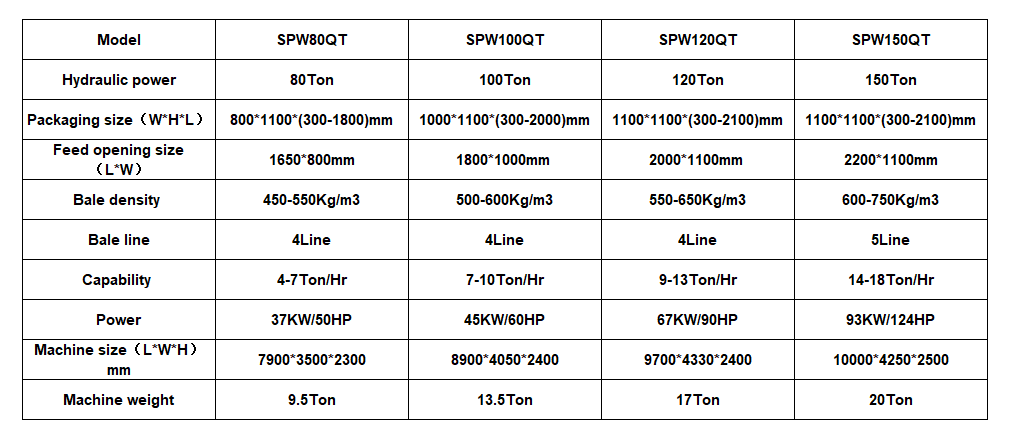

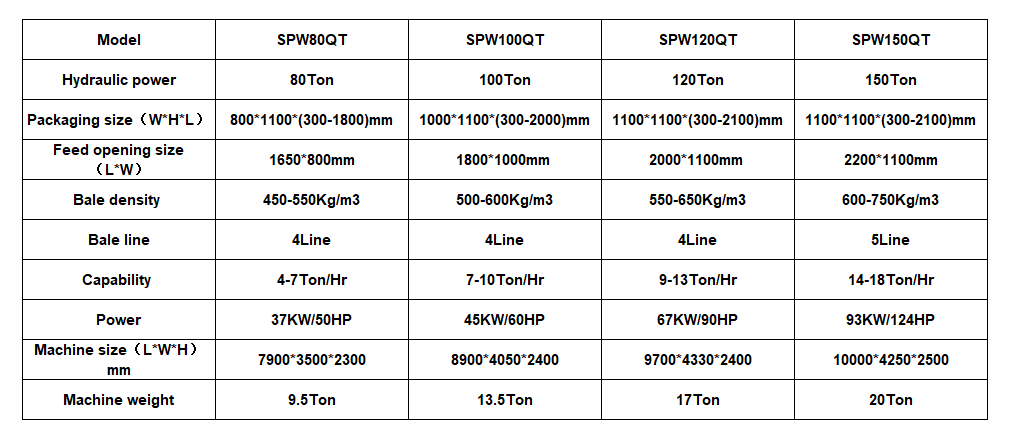

- Model

- SPW120QT/ SPW150QT

Review

Description

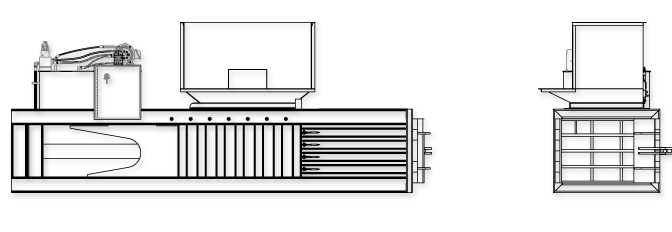

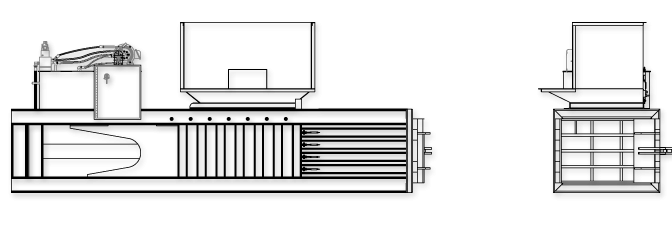

Large-sized horizontal fully automatic hydraulic balers

Ideal for larger quantities of recyclables

Widely used in carton factory, packaging factory,

printing factory, paper -making factory, waste disposal station, waste

recycle station, logistics and other places that can generate plenty of

waste materials and have a request unmanned operation;

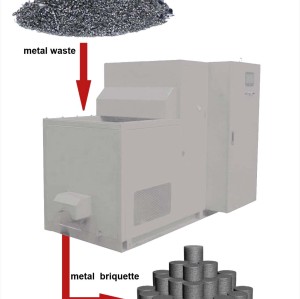

pecially for different leftover material

from waste paper boxes, cardboard, die-cutting machine and plastic, PET

bottles, plastic film, straw, cloth, palm fibers, fiber, cotton and other

loose material

Application:

- Advantages

-

*Automatic press system with force for economical volume reduction of residual (recyclable) materials.

*Variable structure – feed side/bale ejection – can be adapted to spatial conditions

*Easy binding of the pressed bales thanks to pre-cut wires with snap closure eyes.

*Highly reliable and user friendly

- *Flexible

- *Longevity Innovative control system