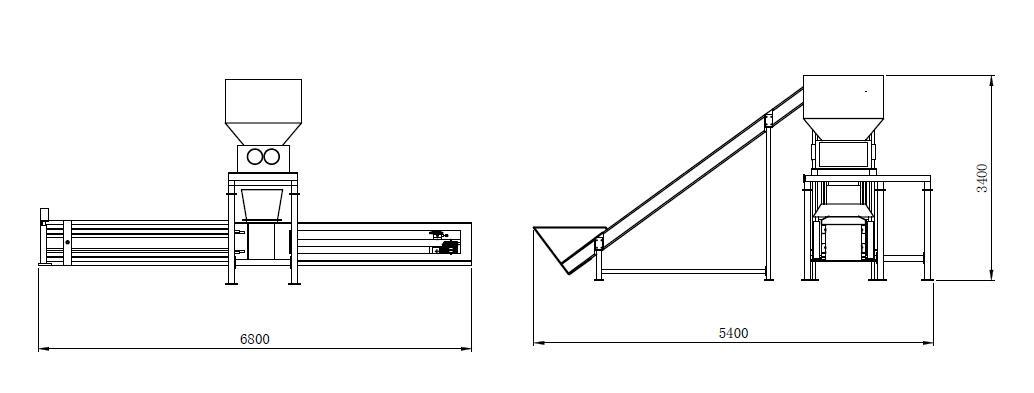

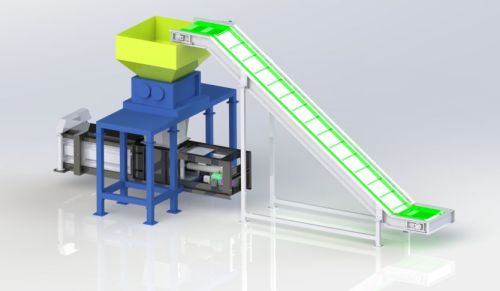

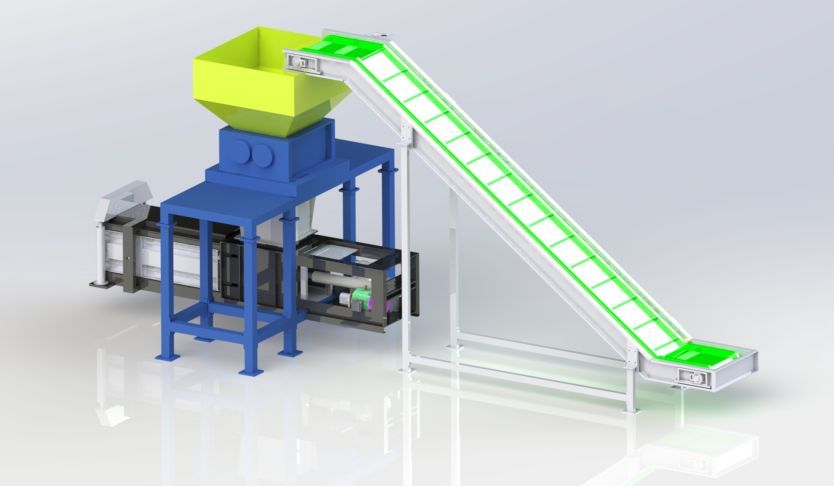

Plastic Bottle shredder and Baler solution

- Model

- SPTW500

Review

Description

Plastic

Bottle shredder and Baler solution

Application

For shredding and baling all types of

plastics bottle. Plastics bottle are labeled with a coded number of one through

seven, typically located on the bottom of the package. But even an avid

recycler may be surprised to see some of the items that are recyclable that

they may have not realized.

#1 PET (Polyethylene terephthalate)

Includes soda bottles, water bottles, oven-ready food trays.

#2 HDPE (High-density polyethylene)

Includes containers from dairy products like milk jugs, yogurt and cottage

cheese. Other items in this code include cereal box liners, and grocery and

trash bags.

#3 PVC (Polyvinyl chloride)

Includes plastic food wrap, loose leaf binders, and vegetable oil bottles.

#4 LDPE (Low-density polyethylene)

Includes squeezable bottles such as mustard and honey, and plastic bags such as

bread bags, frozen food bags and dry cleaner bags.

#5 PP (Polypropylene)

Includes drinking straws, caps to aerosol products, medicine bottles.

#6 PS (Polystyrene) Includes

plastic egg cartons, foam peanuts, plastic tableware, compact disc jackets.

#7 (Other Plastics) Includes other

plastics that can be recycled such as Tupperware and other plastic food

containers, larger reusable water jugs and others.

-

*Small space occupation, low power consumption.

*Easy to operate, easy to clean and maintain,

*Shredder blades adopting steel materials durable in use.

*Multiple models available to fit different materials with different size

*Automatic press system with force for high volume reduction of residual (recyclable) materials.

*Variable structure – feed side/bale ejection – can be adapted to spatial conditions

*Easy binding of the pressed bales thanks to pre-cut wires with snap closure eyes.

Customized to ensure the

maximum production capacity.