What are the basic principles of plastic shredder selection?

- Share

- Issue Time

- Mar 28,2020

Summary

To understand and analyze the specific needs of users, including material type, material and discharge mode, material composition and percentage, need to break the size of the material, roughly follow-up process, cost budget, etc

What are the basic principles of plastic shredder

selection?

To

understand and analyze the specific needs of users, including material type,

material and discharge mode, material composition and percentage, need to break

the size of the material, roughly follow-up process, cost budget, etc.

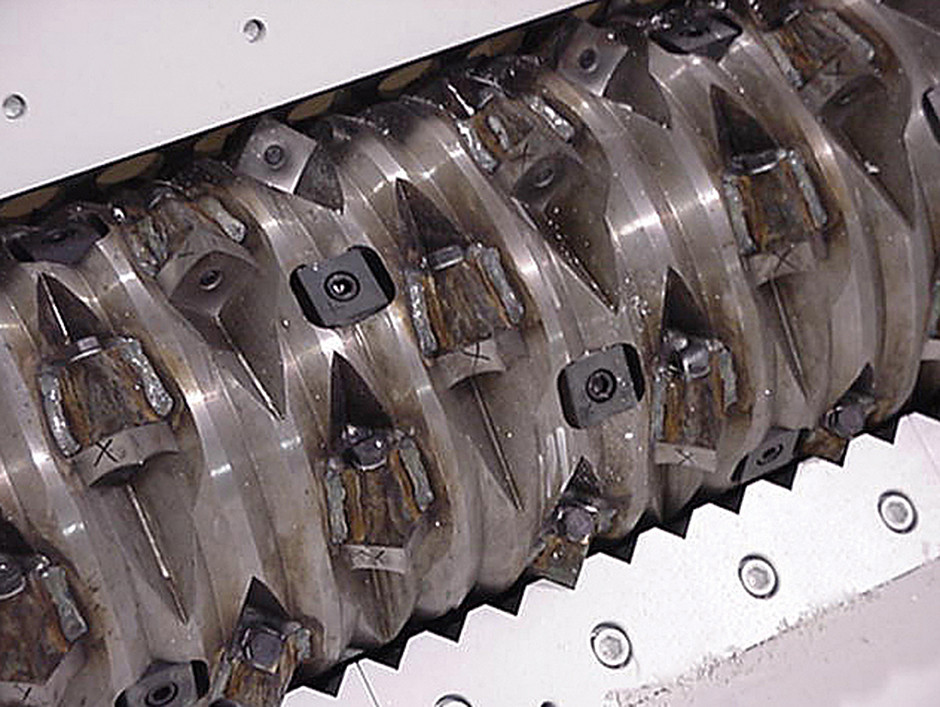

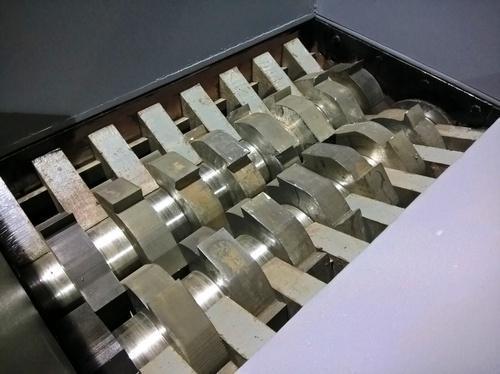

Basis one:

to be broken materials: including size, composition, etc,we will use difference shredding construction

such as single shaft shredder or double shaft shredder base on customers’requirement

Basis two:

output requirements

Yield

requirements are also important. For example, the type of large plastic crusher

used to process 1 ton per hour is different from that used to process 6 tons

Basis three:

crushing size

Generally,

the smaller the size of the crushing material, the higher the cost. Therefore,

it is necessary to make clear the relationship between demand and cost and

profit.

Sometimes

the size of the plant also limits the size of the large plastic shredding

machine and the shape of the production line process. Auxiliary equipment can

be configured according to the actual situation: feeding conveyor, discharging

conveyor, iron remover, trolley, press device, hydraulic drive, packing system,

intelligent dust removal system, intelligent remote monitoring system.